LIGHT UP

YOUR MANUFACTURING

CLOUD-ON PREMISE

COLLECT DATA FROM ALL MANUFACTURING DEVICES AND SENSORS, MONITOR THEM, AND GET PRODUCTION INSIGHTS!

WHAT IS PAMIS?

PaMiS is developed as a hybrid product with microservice architecture.

It is designed as a generic product that will be a solution for supporting all production shopfloors.

Real Time

Monitoring

Anomaly

Detection

Production

Insights

User Friendly

Design

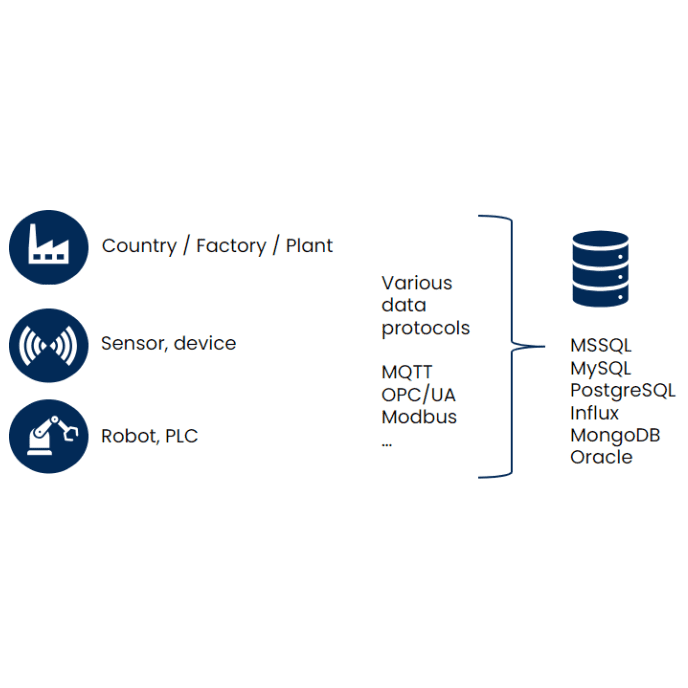

DATA COLLECTION

Data Collection is an IIoT solution that provides collecting all kinds of data from each possible assets including PLCs, machines, sensors and other devices through various protocols.

Thus, it transforms manufacturing machinery into valuable data sources that supply a network of productivity insights.

MANAGEMENT

It is the administrative hub where authorized personnel can create, modify, and deactivate user accounts, defining their groups, roles, permissions, and access levels within the MES platform. This functionality ensures that only authorized individuals can interact with the system, safeguarding sensitive production data and processes.

It serves as a centralized hub for organizing, assigning, and tracking tasks within a manufacturing environment. It enables efficient coordination of production activities, responds to anomalies to address and resolve issues, and ensures that each task is allocated to the right personnel or group, and monitored for progress and completion. This approach minimizes disruptions, ensuring efficient and high-quality production.

It is dedicated to maintaining and enhancing product quality throughout the manufacturing process. It is responsible for upholding product standards, detecting defects, and ensuring compliance with industry standards and regulations, contributing to superior product quality and customer satisfaction.

It is responsible for alerting relevant personnel/groups to critical events, such as production issues or system updates. It ensures timely communication and decision-making, helping to minimize downtime and optimize operational efficiency within the manufacturing environment.

MACHINE LEARNING & AI

The Machine Learning and AI component of PaMiS represents the cutting-edge technology that drives efficiency and intelligence in manufacturing operations. This section harnesses the power of advanced algorithms and predictive analytics to empower your factory with data-driven decision-making. By continuously learning from real-time data streams, it can identify patterns, anomalies, and opportunities for optimization. It constantly fine-tunes processes and predicts maintenance needs, ensuring your factory operates at peak performance and delivers superior results.

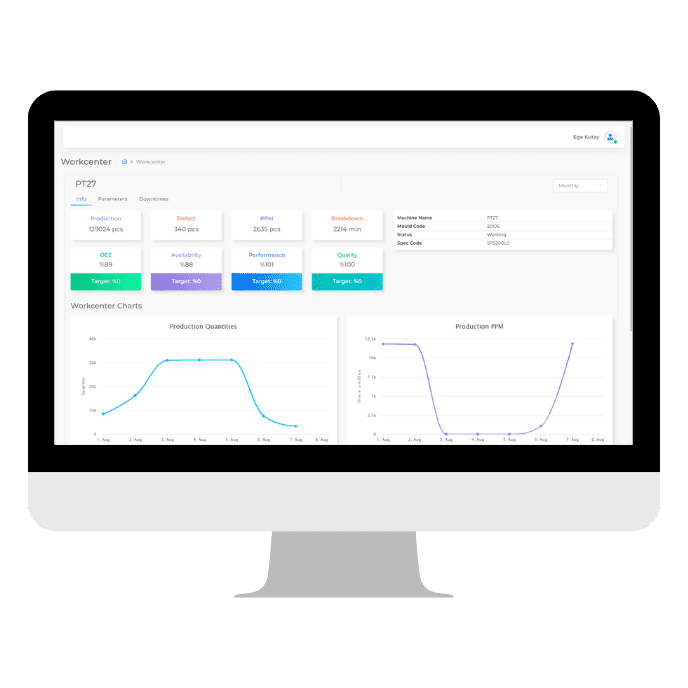

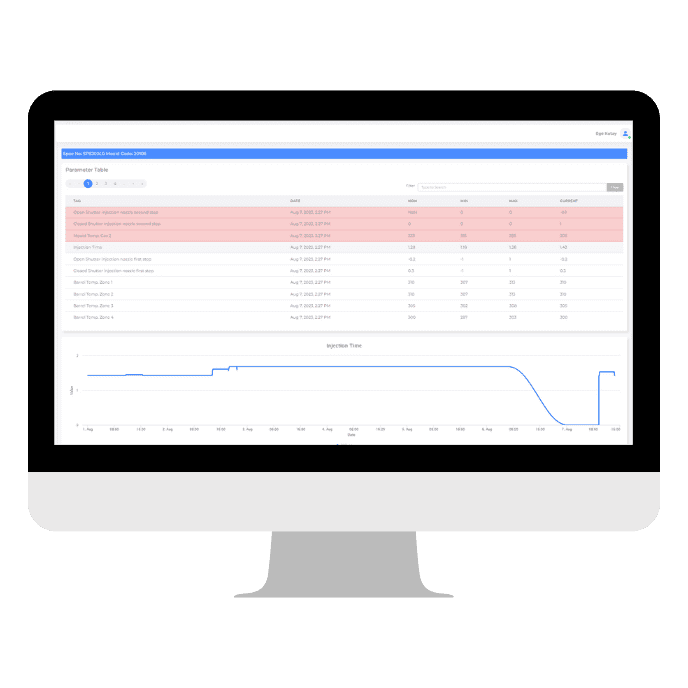

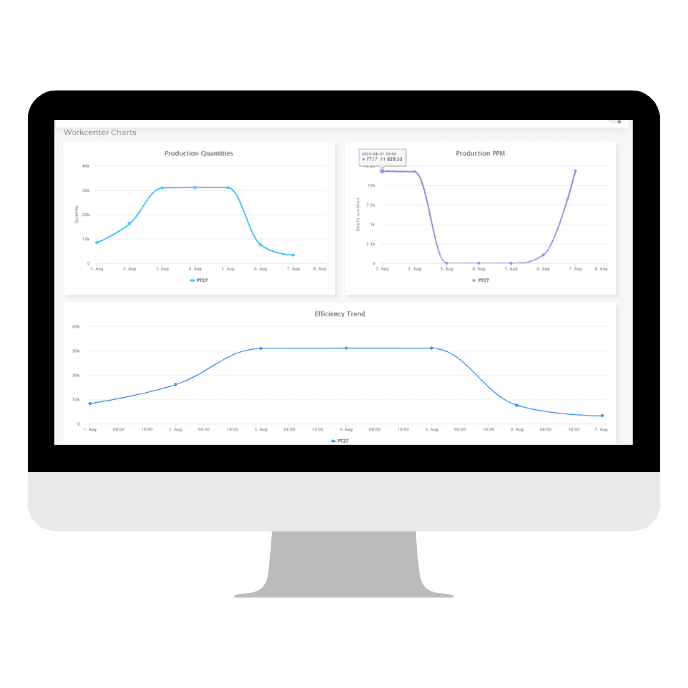

TRACKING & MONITORING

Tracking & Monitoring within PaMiS serves as the eyes and ears of your production environment. It provides real-time visibility into every aspect of your manufacturing process, offering a comprehensive overview of the entire production lifecycle. With its user friendly interface, it provides the ability to closely monitor key performance indicators, detect inefficiencies, and promptly address any deviations, ultimately driving quality improvements, reducing downtime, and enhancing overall operational efficiency.

All Data In One Platform

End to End Solution

Breakdown Tracking

Production Insights

User Friendly Design

INTEGRATION

ERP APPLICATIONS

MES APPLICATIONS

3RD PARTY APPLICATIONS